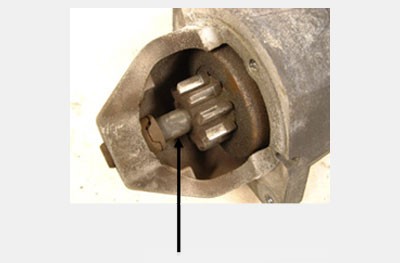

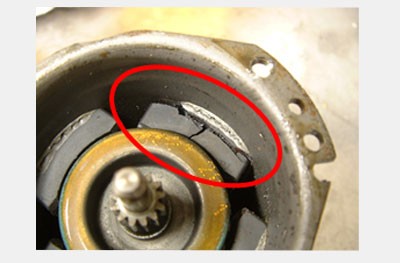

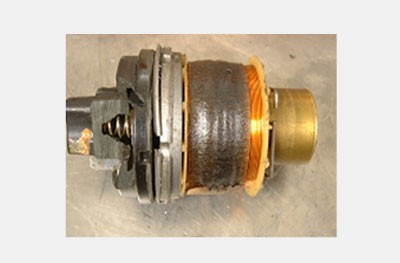

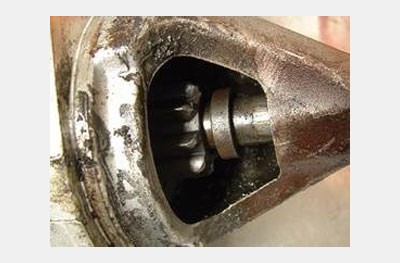

Damage patterns on starters – recognising causes, avoiding failures

The starter, also known as the starter motor, is one of the central components in the starting and charging system. A failure can have all kinds of consequences: ranging from starting difficulties right up to the vehicle coming to a complete standstill.

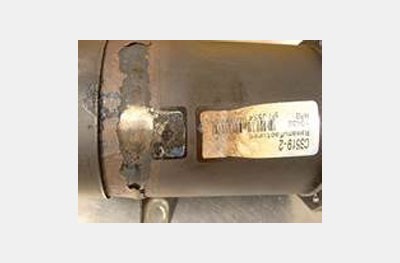

If the starter does not turn, the direct cause of the fault is usually the starter itself, provided that the other components of the starting system are working properly. However, damage is often caused by external influences such as dirt, moisture, mechanical stress or incorrect operation. These factors can affect the starter to such an extent that it eventually fails. If such influences are recognised and rectified at an early stage, repeated failure can be avoided.