Tipos de danos em motores de arranque — Identificar causas, evitar falhas

O motor de arranque é um dos componentes centrais do sistema de arranque e de carregamento. Uma falha pode ter várias consequências: desde dificuldades no arranque até à paragem completa do veículo.

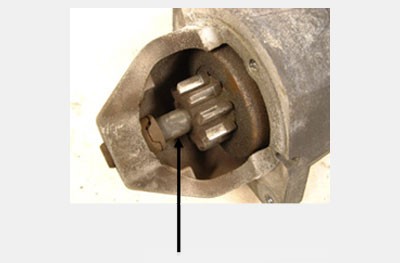

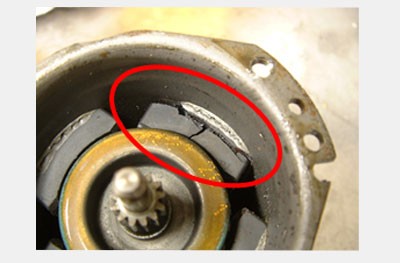

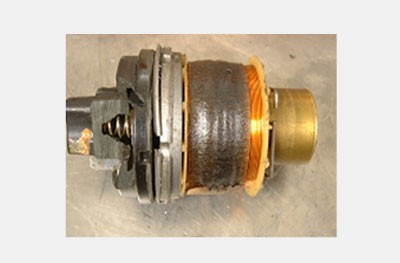

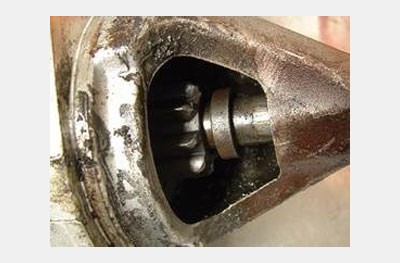

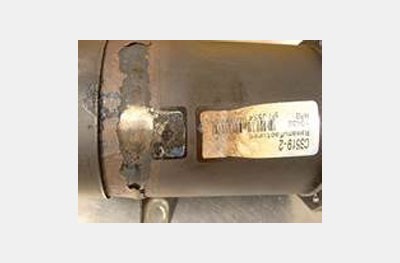

Se o motor de arranque não rodar, a causa do erro imediata está, na maioria dos casos, no próprio motor de arranque, desde que os restantes componentes do sistema de arranque funcionem corretamente. Frequentemente, os danos ocorrem devido a influências externas, como poluição, humidade, cargas mecânicas ou falhas de operação. Estes fatores podem afetar o motor de arranque de tal forma que ele acaba por falhar. Se influências deste tipo forem detetadas e eliminadas atempadamente, pode-se evitar uma falha repetida.