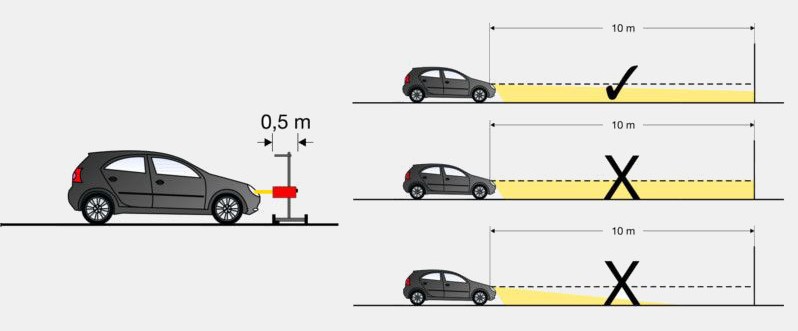

Measurement method

Beamsetters fundamentally simulate the 10 m wall. The lens installed in the beamsetter box shortens the prescribed 10 m distance to 50 cm (Fig. 2 - lens to aiming screen).

The disadvantages, such as high amount of space and a suitable wall, are omitted. A beamsetter can also be flexibly used at different places within the workshop, provided the workshop floor adheres to the required tolerances.