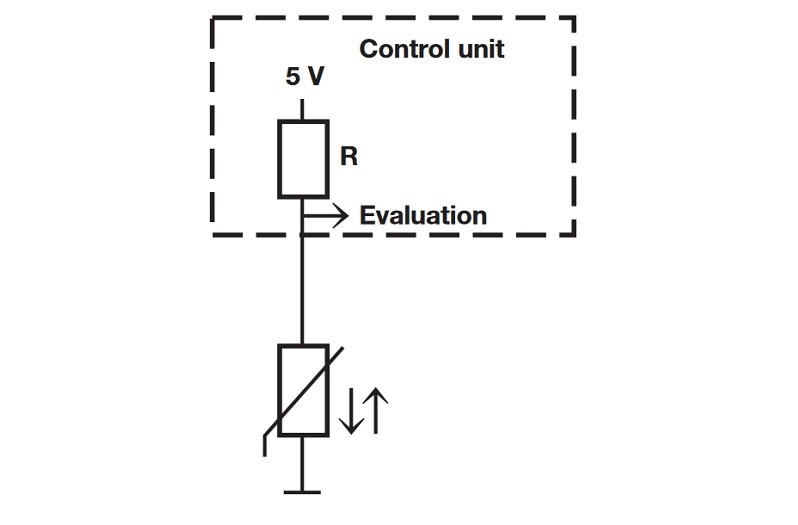

Test step 1

The internal resistance of the sensor is determined. The resistance is temperature-dependent. When the engine is cold it is high-impedance, and when the engine is hot it is low-impedance.

Depending on the manufacturer:

25°C 2.0 – 6 KOhm or 80°C approx. 300 Ohm

Please note the special reference value specifications.