Function and assembly of the alternator freewheel clutch

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their work. The information provided on this website is intended for use by suitably qualified personnel only.

Table of Content

- 1. Basics

- 2. Function

- 3. Benefits

- 4. Mounting instructions

Table of Content

1. Basics

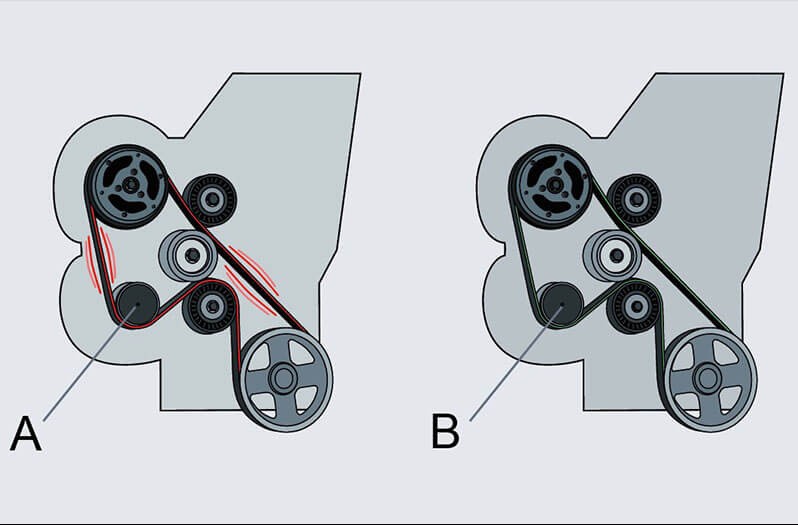

Overrunning belt pulleys on alternators

2. Function

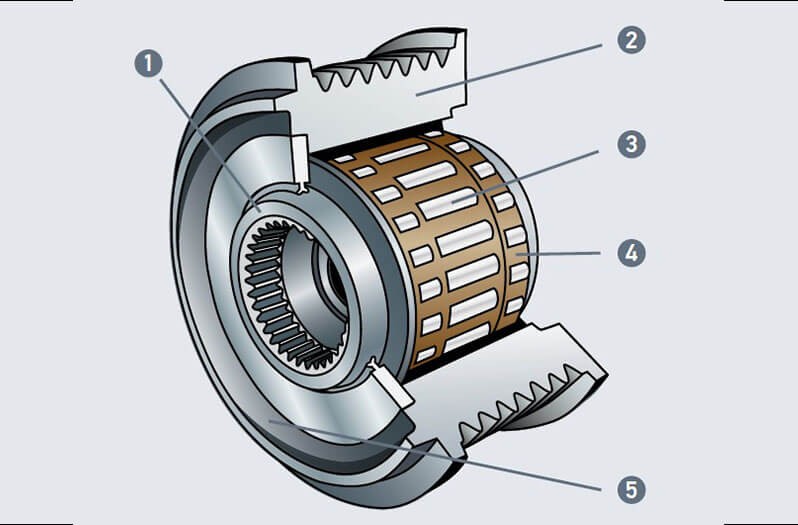

Function and structure of the alternator freewheel clutch

3. Benefits

Advantages of the alternator freewheel clutch

4. Mounting instructions

Installation instructions for alternator freewheel clutch

Important!

Refer to the removal and installation instructions from the relevant

vehicle manufacturer.

vehicle manufacturer.

- Installation may only be carried out by a qualified specialist

- Note tightening torque

- Do not use pneumatic tools

How helpful is this article for you?

Not helpful at all

Very helpful

5

4

3

2

1

Success

Sign up for our free HELLA TECH WORLD newsletter to receive the latest technical videos, car repair advice, training course information, marketing campaign details and diagnostic tips.

Success

Success

Success

Success

Success

Success

Success

Success

Error

Error

Please tell us what you did not like.

Success

Thank you for your feedback!

Wrong Captcha

Wrong Captcha

Error

Something went wrong

You might also be interested in

Basic Knowledge

E-mobility in everyday workshop activities: technology and requirements

Electromobility is changing workshop processes: find out how workshops handle high-voltage systems, new diagnostics procedures and targeted qualifications

Reading Time: 16 minutes

Basic Knowledge

Alternator damage assessment

How to diagnose damage to the alternator: ranging from corrosion and short circuits right up to bearing damage.

Reading Time: 1 minute

Basic Knowledge

Starter damage assessment

Starter faulty? Spot typical causes such as overloading or misfiring and find out how to repair damage effectively.

Reading Time: 1 minute

Basic Knowledge

Intake-air temperature sensor - checking & faults

Discover how to check the intake air temperature sensor for defects and how to replace it efficiently.

Reading Time: 3 minutes

Basic Knowledge

Coolant temperature sensor testing

Instructions for testing the coolant temperature sensor with a multimeter - diagnosis and repair for your workshop.

Reading Time: 3 minutes

Basic Knowledge

Air-mass sensor - Function & troubleshooting

Learn how to check a mass air flow sensor, detect defective sensors and replace them professionally.

Reading Time: 2 minutes

Basic Knowledge

Idle speed controller & actuator - function & check

Everything you need to know about testing and troubleshooting idle speed regulators: function, typical symptoms and repair tips for your workshop.

Reading Time: 3 minutes

Basic Knowledge

Car knock sensor - function & troubleshooting

Find out how to check the knock sensor for malfunctions and rectify possible fault symptoms.

Reading Time: 2 minutes

Basic Knowledge

Accelerator pedal sensor – function & design

Important tips for checking the accelerator pedal sensor and rectifying defects - practical knowledge for your workshop.

Reading Time: 3 minutes

Basic Knowledge

Injection nozzle/injection valve – Function & checks

Find out how to diagnose a defective fuel injector and replace it in the workshop.

Reading Time: 6 minutes