Willkommen bei FORVIA HELLA!

FORVIA HELLA ist ein börsennotierter, international aufgestellter Automobilzulieferer. Wir stehen für leistungsstarke Lichttechnik sowie Fahrzeugelektronik. Zugleich decken wir mit der Business Group Lifecycle Solutions ein breites Service- und Produktportfolio für das Ersatzteil- und Werkstattgeschäft sowie für Hersteller von Spezialfahrzeugen ab.

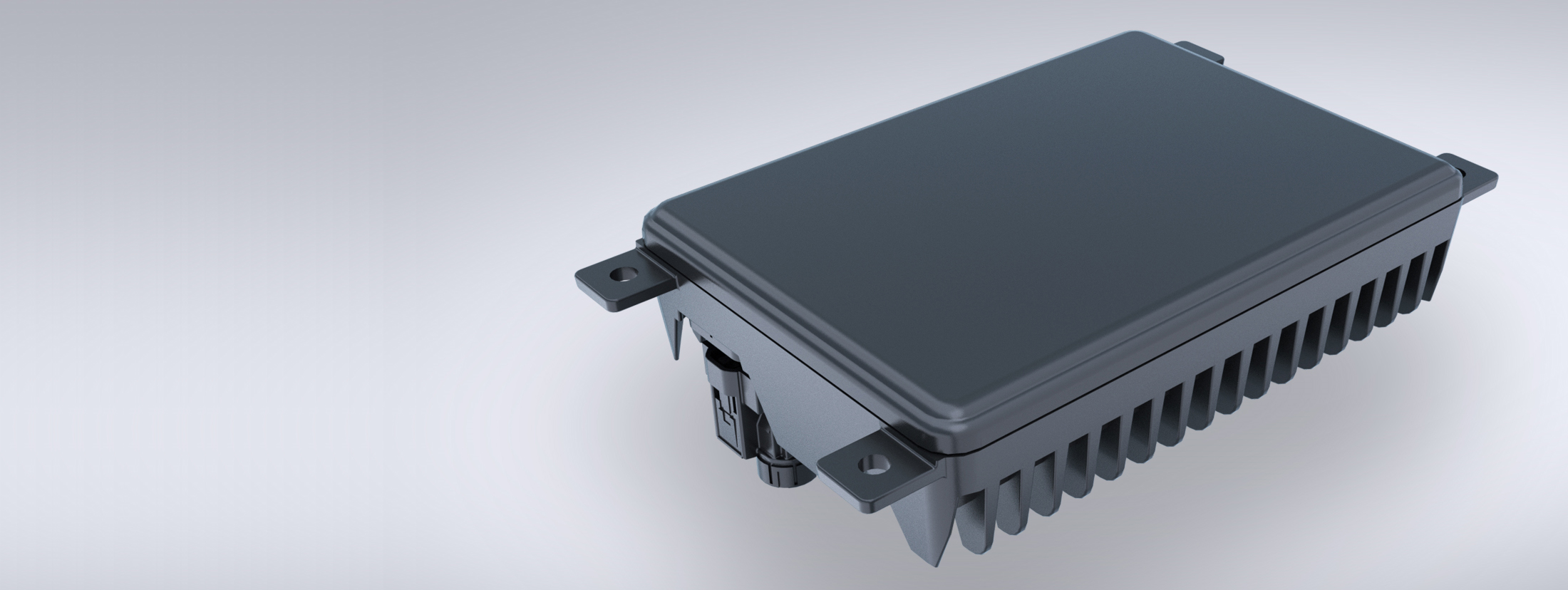

FORVIA HELLA erhält ersten Großauftrag für hochauflösende Radarsensoren

Komplettanbieter für Radarsensorik: FORVIA HELLA erweitert mit High Resolution Radar „ForWave7HD“ das 360 Grad-Radarportfolio.

Mehr erfahrenFORVIA HELLA erhält renommierten CLEPA Innovation Award für FlatLight-Technologie

Innovative Lichttechnik auf Mikrooptik-Basis setzt neue Maßstäbe in Designfreiheit, Skalierbarkeit und Energieeffizienz.

Mehr erfahrenProf. Dr. Peter Laier wird neuer Vorsitzender der Geschäftsführung von FORVIA HELLA

Prof. Dr. Peter Laier wird die Funktion zum Ablauf des 15. Februar 2026 übernehmen und damit die Nachfolge von Bernard Schäferbarthold antreten.

Mehr erfahrenBeliebte Links

Unser Weg zu Klimaneutralität

FORVIA ist das erste Automobilunternehmen mit einem von der Science Based Targets Initiative (SBTi) anerkannten Netto-Null-Ziel.

Mehr dazu