Centralization of thermal management continues: HELLA receives further series orders for Coolant Control Hub

- Further nominations by international and German automobile manufacturers; start of series production planned for 2024 and 2025

- Higher efficiency of electric cars and lower costs by connecting different cooling circuits in the vehicle

- Flexible adaptation to customer requirements through modular, integrative platform approach

Lippstadt, 8 December 2022. HELLA, the automotive supplier operating under the umbrella of the FORVIA Group, has won two more customer orders for its innovative Coolant Control Hub (CCH). Having already received the first series order for the CCH from a leading international automobile manufacturer in the middle of this year, HELLA will now also bring the Coolant Control Hub into series production for its all-electric pick-up or light truck platform. HELLA has also received a series order for the performance line of a German premium manufacturer. The start of series production for these customer projects is planned for 2024 and 2025.

"We have now already received three significant customer orders for our new, innovative Coolant Control Hub within just a few months. This shows that the centralization of thermal management in electric vehicles is continuing to accelerate and that we are playing a key role in shaping this trend with our products," says Björn Twiehaus, Managing Director Electronics at HELLA. "In addition, the two series orders we recently won underscore the fact that we can use the modular approach of the CCH to precisely address different vehicle classes with their respective requirements."

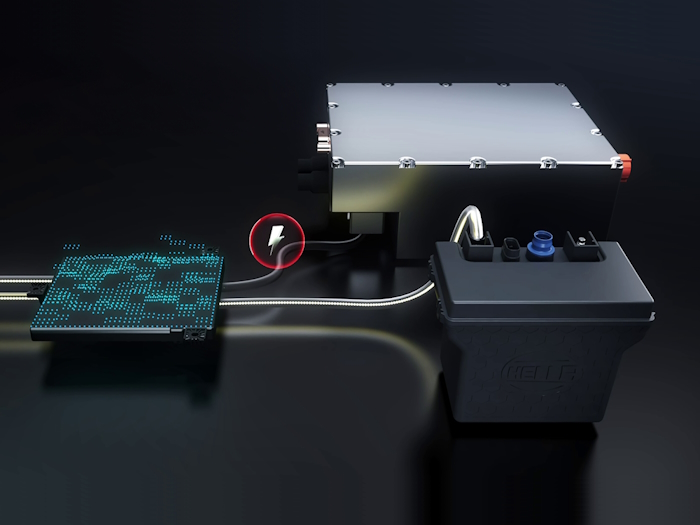

HELLA's Coolant Control Hub connects the cooling circuits for the battery, electric motor and vehicle interior. Through this centralization, the CCH on the one hand ensures higher efficiency, shorter charging times and longer ranges for electric cars, as the thermal energy is optimally distributed. On the other hand, the components required in the overall system can be reduced by up to 50 percent, thus also saving costs for materials, logistics and assembly. Because the CCH is based on a modular, integrative approach, it is offered as a customized subsystem that can be tailored to meet specific customer specifications. In the application of the Coolant Control Hub for the performance variant, for example, a major focus was on the high requirements in terms of cooling demand as well as the correspondingly large amount of waste heat with high power density. With the help of the CCH, it is therefore ensured that the required coolant can be routed as needed, the waste heat efficiently dissipated and also reused if necessary.

The Coolant Control Hub will first start up in 2024 at HELLA's electronics plant in San José Iturbide, Mexico. The other series projects for which HELLA has now been commissioned will also be manufactured in San José Iturbide and in Arad, Romania. Development takes place in the international HELLA network, including in Northville (USA), Guadalajara (Mexico), Timişoara (Romania) and at the company's headquarters in Lippstadt (Germany).

Contact

Press Officer

Rixbecker Str. 75

59552 Lippstadt

Phone: +49 2941 38-7566

Fax: +49 2941 38-477545