Coolant pumps | HELLA

General

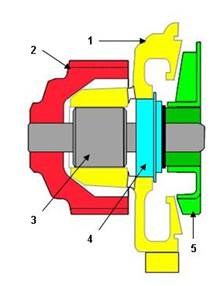

Coolant pumps (Figure 1) are mostly driven mechanically, by a toothed belt or V-ribbed belt, and transport the coolant through the engine's coolant circuit. The pumps can be flanged directly to the engine or also installed away from it. The designs are quite different. Coolant pumps must withstand huge variations in temperature (-40 °C to approx. +120 °C). Changing speeds (500 - 8000 rpm) and pressures of up to 3 bar require high stability of bearings and seals.

To save fuel, electrically driven and electronically controlled pumps will increasingly be used in the future.

Figure 1

Figure 1

Design/principle

A mechanical coolant pump consists of the following 5 sub-assemblies (drawing):

- Body

- Drive gear

- Antifriction bearing

- Mechanical seal

- Vane

The drive gear and the vane sit on a common shaft. A mechanical seal seals off the pump shaft towards the outside. The rotation of the vane transports the coolant through the cooling system. Vanes are usually made of plastic or metal. The bearing load is lower with plastic vanes. At the same time, they are not as susceptible to cavitation.

However, plastic vanes sometimes become brittle with age.

The mechanical seal (Figure 2) is always lubricated and cooled by the coolant. Due to the design, minimal amounts of coolant can enter the space behind the seal and exit at the relief hole of the pump. Traces of coolant that may be visible are no clear indication of a defective pump.

Drawing

Effects of a failure / causes

A failure of the coolant pump can manifest itself as follows:

· Noise

· Loss of coolant

· Inadequate cooling / engine overheats

These are possible causes:

· Mechanical damage:

Loose/broken vane

Bearing or seal broken

Drive gear damaged

· Cross-section constricted by corrosion or sealant

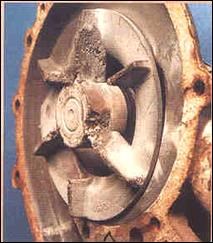

· Cavitation:

Damage to the vane by the forming and collapsing of vapour bubbles in the coolant (Figure 3)

· Electrical fault (short-circuit/interruption)

Figure 3

Possible damage patterns

Drive gear damaged (loose drive gear ring), Figure 4:

· tension of the control belt too high

· Misalignment of the belt

Fraction of the water pump bearing (bearing retainer):

· Heavy vibrations by defective Visco clutch

Coolant leakage from the pump by, e.g.,:

· Excessive application of sealant

Figure 5

Remains of the sealing compound (Fig. 5) may enter the cooling circuit and damage the mechanical seal, for example. Corrosion in the entire cooling system (Figure 6):

Corrosion in the entire cooling system (Figure 6):

· Defective cylinder head gasket - engine exhaust gases enter the cooling system. Negative variation of pH

Pump parts such as vane, body, mechanical seal

Figure 6

and shaft severely damaged by hole corrosion (Figure 7):·  Old/stale coolant with high content of chlorides (salt compounds) in conjunction with elevated temperatures.

Old/stale coolant with high content of chlorides (salt compounds) in conjunction with elevated temperatures.

Excessive leakage of coolant from the relief hole (Figure 8):

-

Figure 7

Caused by corrosion in the cooling system

Figure 4

Figure 4

Notes on removal and installation

Always follow the instructions on the product leaflet and special installation instructions of the vehicle manufacturer when replacing the coolant pump. If the cooling system is contaminated, it must be flushed. This can be done, e.g., with cooling system cleaner 8PE 351 225-841. The cooling system should only be filled with a coolant that meets the specifications of the vehicle manufacturer. The system must be filled or vented according to the instructions of the vehicle manufacturer. An incorrect installation can lead to overheating of the engine, damage to the belt drive or/and engine damage.

For information on use, specifications, and change intervals of coolants, see the appropriate Technical Information “Coolant”.

Figure 8

Figure 8

Important safety notice

The following technical information and tips for practical use have been set up by HELLA in order to offer professional support to automotive workshops in their daily work. The information available here on this website is only to be used by appropriately trained specialist staff.

The reprinting, distribution, reproduction, exploitation in any form and disclosure of the contents of this document, even in part, is prohibited without our express written approval and indication of the source. The schematic illustrations, figures and descriptions are for explanation and presentation of the document text and cannot be used as a basis for installation or design. All rights reserved.

Not helpful at all

Very helpful